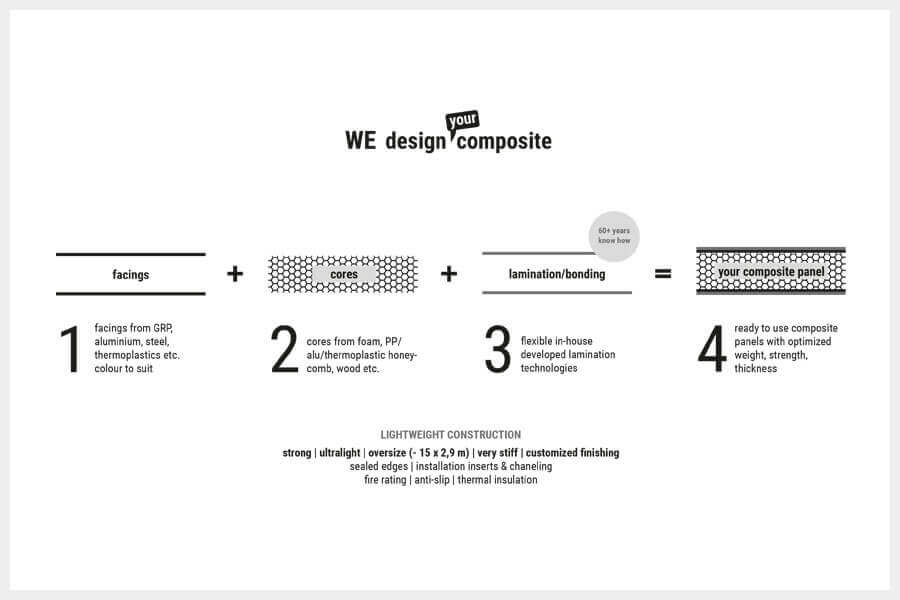

Robust lightweight panels with foam or honeycomb cores

The highly durable and stable sandwich elements with foam or various honeycomb core variants of the TOP series are mainly used in commercial vehicles, industry and for balcony and terrace floors. The composite panels that can be combined with different facing sheets for vehicle and container construction as well as in special applications for a wide variety of industrial sectors have a particularly high priority. Likewise, the lightweight design with design composite elements is appreciated as a high-strength and flexible alternative for scaffolding and pedestal construction or for facades.

Design composite sandwich panels of the TOP series are distinguished by a particularly low weight with the highest technical characteristics. Standard products with the same thickness have a weight of up to +30%. design composite does not work with only one production technology as many manufacturers in this sector but offers its customers the best solution for their requirements.

Ultra-light

The design innovation of design composite lies in the unique and flexible manufacturing process, which makes it possible to offer extremely light panels.

Stability

Highly durable elements with high stiffness using foam, PP or aluminium honeycomb cores and glass fibre reinforced plastic (GRP) or aluminium facing sheets for a wide range of applications.

Individual

The entire range is characterized by a high degree of flexibility and finishing depth (design your composite supplementary service).

Light-weight elements up to a size of 15 x 2.9 meters can be developed and produced for individual requirements.

Highly robust composite panels with different cores and facing sheets

design composite TOP-series

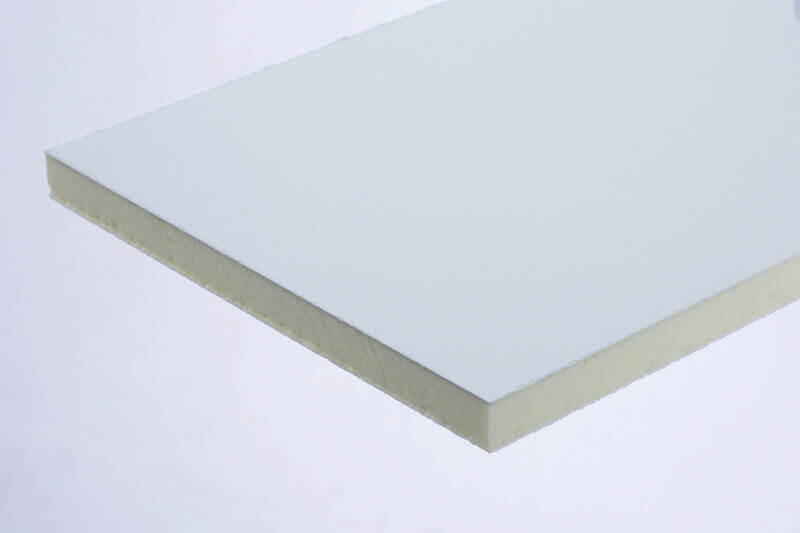

Foam core

TOP-lite® GRP | TOP-lite® GRP ultra | TOP-lite® ALU | TOP-lite® STEEL | TOP-lite® WOOD

Hard foam core with glass fibre reinforced polyester, epoxy, aluminum, HPL or other facing sheet materials.

Particularly suitable for light truck construction, truck bodies, special trucks and event vehicles, containers, housings, wind power housings, façades...

PP-honeycomb cores

TOP-air GRP | TOP-air GRP ultra | TOP-air ALU | TOP-air power GRP | TOP-air power GRP antislip | TOP-air STEEL | TOP-air WOOD

PP-honeycomb cores with glass fibre reinforced polyester, epoxy, aluminum, HPL or other facing sheet materials.

Particularly suitable for light truck construction, truck bodies, special trucks, pedestals, balcony floors, housings.

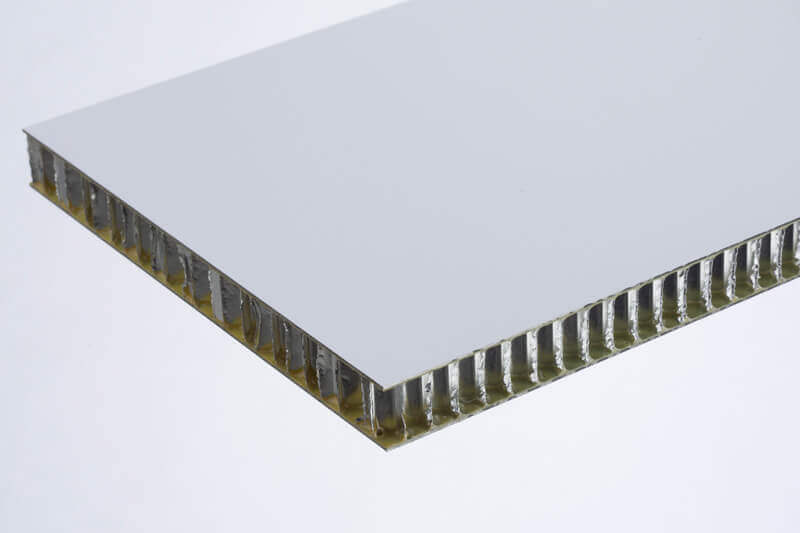

ALU-honeycomb cores

TOP-tec ALU | TOP-tec WOOD | TOP-tec STEEL

ALU-honeycomb cores with alu/steel or HPL/wood facing sheets for applications with extremely high demands for stability and stiffness or increased fire resistance requirements and temperature dissipation.

Particularly suitable for carrier panels, machine housings, flood protection

design your composite

The products of the TOP series can be combined as desired and individually arranged according to requirements. In addition to the standard products with foam core, PP or aluminium honeycomb, composite elements with plywood core can also be produced. In addition, the flexible modular system of the TOP series offers a multitude of additional facing sheets and finishing possibilities.

This allows the sandwich elements to be tailor-made for your specific needs - from the single piece to the start of serial production.

We are looking forward to your request and will be happy to advise you on your individual project!

Commercial vehicles | Kofferaufbau

Commercial vehicles | Sonderfahrzeuge

Container | Container

Industrial application | Trägerpaneele/Schalungen

Industrial application | Windkraft

Terraces | Balkon/Terrasse